Latest News

SEMulator3D Virtual Fabrication Bundle

All SEMulator3D users will be upgraded to SEMulator Virtual Fabrication Bundle free of charge. SEMulator3D Virtual Fabrication Bundle includes:

-

SEMulator3D Basic

Package containing everything necessary to simulate and view complex CMOS process flows using the voxel modeling engine. Voxel modeling is extremely efficient and ideal for modeling unit process steps that can be characterized geometrically; for example, lithography, spin-on deposition, and wet etches. -

SEMulator3D Advanced Modeling

Provides accurate physics-driven process models for advanced technologies. A powerful, predictive modeling tool to build process understanding, mitigate technology risk and eliminate cycles of learning in technology development. With minimal input parameters that are easy to calibrate, process engineers can gain significant understanding of the behavior and variability of etch and epitaxy steps and their ramifications in the context of the full technology flow. -

SEMulator3D Automation

Automate large number of experiments and use metrology to measure critical geometry. Structure search inspects entire build area for design/process violations.

SEMulator3D

SEMulator3D Virtual Fabrication Bundle

Starting from input design data, SEMulator3D Virtual Fabrication Bundle follows an integrated process flow description to create the virtual equivalent of the complex 3D structures created in the fab. Comprises SEMulator3D Basic, SEMulator3D Advanced Modeling and SEMulator3D Automation.

Base Version

SEMulator3D Datasheet

SEMulator3D is a powerful 3D semiconductor and MEMS process modeling platform that offers wide ranging technology development capabilities. Based on highly efficient physics-driven voxel modeling technology, SEMulator3D has a unique ability to model complete process flows.

Using unique physics-driven 3D modeling technology, the SEMulator3D modeling engine can model a wide variety of unit process steps. Each process step requires only a few geometric and physical input parameters that are easy to understand and calibrate. Just as in an actual fab, upstream unit process parameters (such as deposition conformality, etch anisotropy, selectivity, etc.) interact with each other and design data in a complex way to impact the final device structure.

SEMulator3D Viewer shows a 3D rendering of the virtual device model at every step in the process. Step-by-step visualization can aid in understanding process failure modes and other complex process phenomena. Cross-sectioning and dimensional measurements can be performed anywhere on the 3D model. SEMulator3D Viewer has many advanced capabilities, including automatic animation of process steps and automatic export to Microsoft PowerPoint.

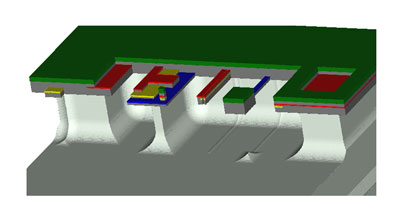

CMOS -MEMS cross section view.

SEMulator3D Advanced Modelling

SEMulator3D Advanced ModellingThe SEMulator3D Advanced Modeling package is a powerful, predictive modeling tool to build process understanding, mitigate technology risk and eliminate cycles of learning in technology development. With minimal input parameters, process engineers can gain significant understanding of the behavior and variability of step in the context of the full technology flow.

SEMulator3D Automation

SEMulator3D AutomationThe SEMulator3D Automation package enables automated parameter variation studies and related data analysis, and includes both SEMulator3D Metrology and SEMulator3D Expeditor. SEMulator3D Metrology mimics actual metrology operations, providing in-line measurements of device structure. SEMulator3D Expeditor performs parameter variation studies, collecting related data for analysis.

Coventor Classroom Teaching Licenses

The Microelectronics Support Centre at RAL is pleased to offer Coventor Classroom Teaching Licenses to EUROPRACTICE members.

EUROPRACTICE Coventor Classroom Teaching licenses are intended to enable mass class teaching of students, in cases where an Institute has too few regular EUROPRACTICE non-commercial research and training license seats for that purpose. The Classroom Teaching licenses will be subject to all the usage restrictions of the regular EUROPRACTICE Coventor licenses.

Teaching licenses comprise 20 full licenses for a 6 month duration within a 12 month window and are free of charge and subject to approval by Coventor. To be eligible for teaching licenses, an Institute must pay an annual charge for a purchased license for that product. As part of the ordering procedure, the Institute must supply a syllabus for the proposed training course.

The Coventor Classroom Teaching Licenses prices and order forms can be accessed via the EUROPRACTICE Members Only webpages.

SEMulator3D Operating Systems

- Windows 10 Professional 64-bit

- Red Hat Enterprise Linux 6 and 7 64-bit